How does the DynaTrac guidance interface position all implement accurately and repeatably?

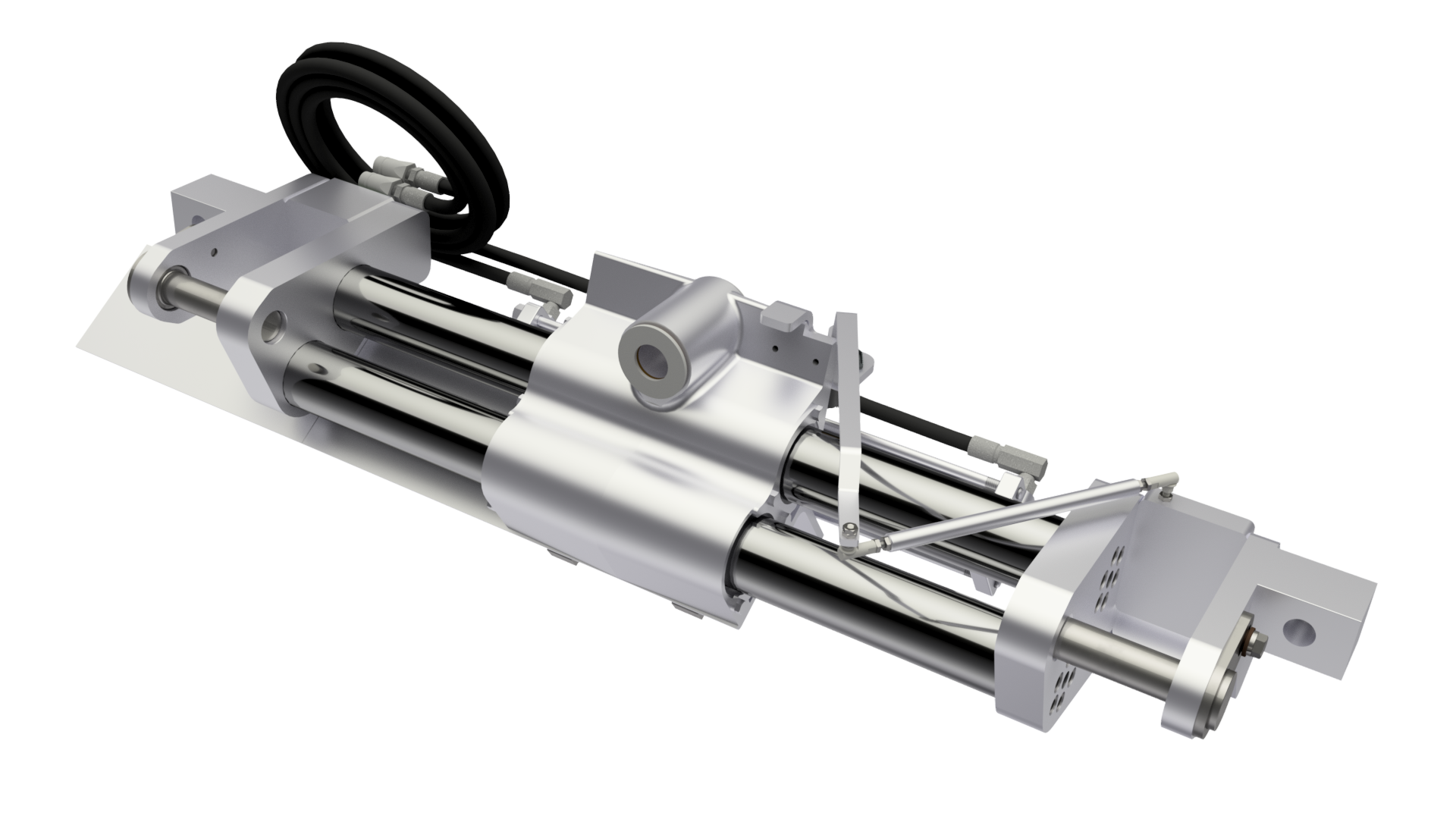

First, DynaTrac consists of a module at the rear of the tractor which shifts laterally to adjust the position of the rear implement. It does that constantly to warrant that the implement remains on the same GPS guidance path (A- B line) as the tractor. Some call it a shifter.

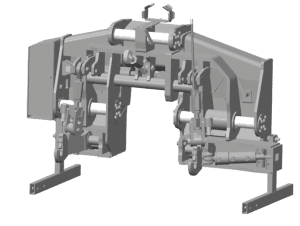

DynaTrac 3-point version

Secondly, DynaTrac goes for a range of universal guidance interfaces also called side-shift hitches.

DynaTrac exists in several 3-point versions which allows to be confident that there will always be the right DynaTrac for a type of tractors and implements. Indeed, each version fits a wide range of tractor rear hitches and farm implements. It can receive 3-point, 2-point and pulled implement to offer versatility.

In the 3-point versions, DynaTrac replicates a tractor rear hitch with all the well-known benefits of this design for easily connecting implement and adjusting their position.On top of that, it adds the shifting feature which allows to position it accurately making it a smart rear hitch. It is also called a Smart Quick Coupler. This is the perfect equipment for any farmer willing to implement precision farming.

Discover why implement guidance a straight path to higher profits !

Why is it, truly, the best guidance solution for a farm?

Switching implement easily and quickly

First, DynaTrac offers 3-point connection. Consequently, the guided implement can change easily and quickly. With other implement guidance systems like steering discs (or steering blades) specifically fitted to the rear of the implement, it consumes much more time, tediously. Being usable with all implements, it makes precision possible for each field operation. As a benefit, it pays off faster as each path leverages accuracy for better yield or less crop damage.

Less need for correction, more accuracy

In addition, DynaTrac 3-point range incorporates a patented design giving the option to work with the lower links of the DynaTrac in float position. It makes it smoother to steer. Benefits lie in more accuracy and less need for position correction. Indeed, the system not being rigid like other side shift hitches in the market, it does not push the tractor on one side when the implement shifts in the other direction. There is no more interference between the tractor guidance system and the implement guidance system. Many customers were enthusiastic about it when they saw it operating in their field so efficiently.

A rigid shifting interface can also be an issue when working with ground engaging or heavy implements (bed ploughs, strip-till, etc.) as this would bend the shanks of the implement or move the tractor but not the implement, generating extra inaccuracies. All these issues settle with the float position of the DynaTrac guidance interface when used with 3-point implements.

Arms on float or locked, at your convenience

Of course, the lower arms of the DynaTrac can get locked when needed. It can be done automatically (in headland management settings) with 3-point implements when lifted for U-turn to ensure that it centers and when driving on the road. This is also the case to pull implements which have a pivot point integrated in the tongue.

Complementary to the lateral float option explained above, the DynaTrac 3-point range also offer a vertical float feature. This allows to have the implement weight on the tractor when needed to improve steering authority and have a better driving control. It also guarantees that the implement will always be parallel to the ground. For instance, in a field with slopes, the tractor tires compress more on one side. Without vertical float function on the guidance interface, the implement will not work at a homogenous depth which is detrimental at planting for example.

How is DynaTrac steered to ensure high accuracy positioning of the implement?

A key component to operate DynaTrac is the positioning system. Several solutions exist to adjust DynaTrac position (hence also implement) in real time: