Position all your implements with precision and repeatability!

Economical, simple, and unique, the universal guidance interface DynaTrac is compatible with all models of tractors equipped with an RTK (or camera) guidance system and fits with all implements.

Capitalizing on several years of R & D and sales in the United States and Europe, DynaTrac range of interface makes it possible to follow the tractor path with any implement. It allows using standard implements and reaping the benefits of precision farming at every stage of the crop.

UNIVERSAL GUIDANCE INTERFACE

Why DynaTrac® ?

GPS tractor guidance benefits are recognized by farmers around the world. They ensure repeatable tractor positioning but implements never trail perfectly behind the tractor.

Reasons for implements inability to follow the tractor accurately :

- Slopes where the implement drifts, driven by its weight

- Flat fields – implements can drift laterally due to:

- Uneven soil condition across implement working width

- Unsymmetrical pull due to implement configuration

Benefits

✔ Efficiency: a DynaTrac® interface coupled with a guidance system (GPS or camera) allows farms to instantly get ready for precision farming with their current range of implements and the ones to come.

✔ Simplicity: the user only needs to understand and set up one kind of interface instead of a specific one for each implement.

✔ Savings: Compatible with all tractors and all implements in the marketplace, the DynaTrac® adds the guidance function to standard implements. It is an economical solution instead of buying an implement-dedicated guidance function on each implement.

✔ Agronomy (some examples):

• Strip-till implement guided to only till area to be seeded, allowing to reduce fuel consumption and limit soil disturbance. Place seeds at a later stage accurately by guiding planter with DynaTrac® as well.

• Planting with regular spacing between rows on the whole field allowing:

Mechanical termination of weeds (cultivator). Possibility to work even at early / late stage of plant growth, in windy or in poor light conditions because of GPS signal.

Harvest optimized and fast with no guess rows and harvester guided by seeding line.

• Efficient bedding and planting of vegetables- thanks to accuracy preventing overlaps and poor positioning which generate yield losses.

• Fertilizer applied as close as possible to the roots, whatever the growth stage of the plant. Savings for the farmer and decrease of fertilizer application rate positive for the environment.

• Drip irrigation:

allows to position irrigation tapes precisely and then plant close to them to boost yields while limiting water consumption.

Allows subsequent operations without damaging irrigation tapes grids.

Guidance

GPS

Efficient : guarantees working precision of the rear implement at each step of the crop

Cost effective : guidance function is purchased only once and can be used with all farm’s implements

Optimized mechanical weeding : eliminates the constraints of camera guidance as it doesn’t require the crop to be visible :

- Before crop emergence

- In tricky visual conditions

- When the camera cannot discriminate weeds from the crop

GPS implement guidance system available :

AIG John Deere, True Tracker Trimble, SmartSTEER Homburg, PSR Reichhardt.

VISION

Great fit to guide only a mechanical weeder and offered as option, the Vision pack (DynaTrac & Camera) is:

- Universal : can be used with all kind of row crop cultivators (new, already owned, etc.)

- Profitable : guidance function is purchased only once and can be used with several RC Cultivators with different row spacing (corn, sugar beet, cereals, etc.).

- Flexible : Once guidance benefits are validated with Camera guided RC cultivator, user can switch to GPS guidance

- Performance :

- Working accuracy increased as no interference of tractor and implement movements

- Less wear of working elements as they always move to the front, even when shifting

DynaTrac® range

COMPACT

Specifically designed for light tractors, the DynaTrac® COMPACT features an exclusive design allowing it to accommodate all implements, including those requiring PTO compatibility.

- Hitch tractor side: Cat.2

- Travel range: 30 cm / 12″

- PTO transmission compatibility: YES

- Maximum implement weight (as per ISO standard reference): 1,500 kg / 3 300 lbs

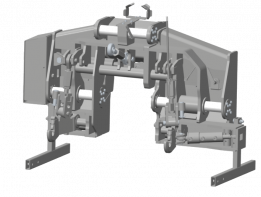

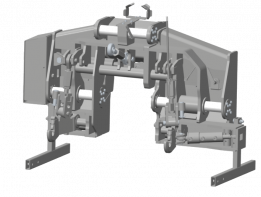

PREMIUM

DynaTrac® PREMIUM has a lateral shift of 25 centimeters on each side but doesn’t fit implements requiring PTO. It is very suitable to drive a row crop cultivator or any implement without PTO connection.

• Travel range : 50 cm / 20’’

• PTO drive line compatibility : NO

• Maximum implement weight (as per ISO standard reference): 4 000 kg / 8 800 lbs

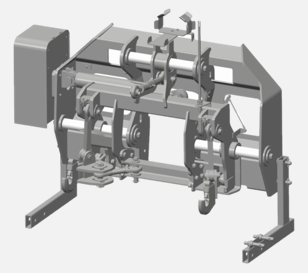

PREMIUM+

Suitable for medium-power range tractors, DynaTrac® PREMIUM+ features an exclusive design allowing it to receive all implements, including those requiring PTO compatibility.

• Travel range : 30 cm / 12’’

• PTO drive line compatibility : YES

• Maximum implement weight (as per ISO standard reference): 5 000 kg / 11 000 lbs

Discover the Profi Test Report :

ULTIMA

Engineered for high horsepower tractors, DynaTrac® ULTIMA features an exclusive design allowing it to receive all implements, including those requiring PTO compatibility.

• Travel range : 50 cm / 20’’

• PTO drive line compatibility : YES

• Maximum implement weight (as per ISO standard reference): 7 500 kg / 16 500 lbs

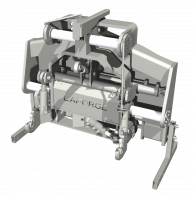

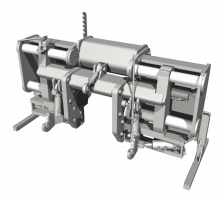

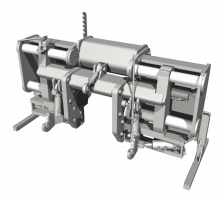

CLASSIC

DynaTrac® CLASSIC is ideal for pulled implements (may require an adapter depending on implement tongue connection).

• Travel range : 50 cm / 20’’

• PTO drive line compatibility : NO

• Max power tractor : 400 HP

![]()

![]()

Les DynaTrac® COMPACT, PREMIUM, PREMIUM+ & ULTIMA have an exclusive design that replicates all the features of a tractor rear hitch. This allows positioning of the implement easily, precisely and with repeatability by following the instructions of the guidance system.